Filter systems are used as primary screening to separate large particles from your wastewater. Removal of these particles prevents downstream pipe blockages and protects upstream equipment.

The Aquarake is a self-cleaning channel filter, with an endless belt of filter elements, which will transport and discharge the retained solids. Hot water spray system and brush cleaning are optional items on the screen.

The curved screen is a straightforward static filter, equipped with a wedge wire sieving plate. A pneumatic controlled sparing system installed with cover will clean the curved screen periodically.

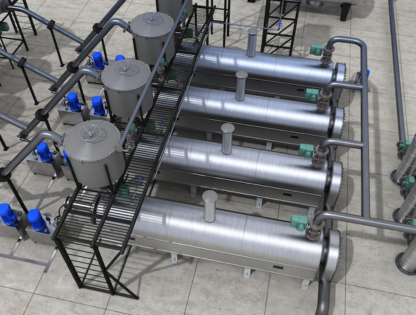

The internally fed rotary drum screen is equipped with a patented inlet water distribution system. A perforated drum with screw will retain and transport the solids from the wastewater. An overflow system is standard.

The cloth filter is an inside fed rotary drum screen with a perforated drum covered by a cloth, specially designed for removal of fine solids. Suitable for specific applications for example solid/liquid separation of manure.

Designed to remove heavy settling and floating particles from water without the addition of chemicals and energy. Also used to recover valuable materials from water, without any contamination of additives, for sale or reuse.

Robust and straightforward lamella settler to remove ‘heavy’ particles from wastewater. Sediment removal by time-controlled pneumatic valves.

Specific wastewater streams, sand and sediment from settlers and flotation units can be automatically removed and concentrated by the sand separator.

Operates by using gravity to separate oils from oil contaminated streams in a concrete basin. All internals of the CPI separator are part of our product programme.

Standardized module which can be integrated in CPI designs.

Operates by using gravity to separate oil from oil contaminated streams. The stainless steel unit is prefabricated in our workshop either with skim pipe or scraper system.